Guide to Choosing paper corner protector machine equipment

1. Core functions and performance

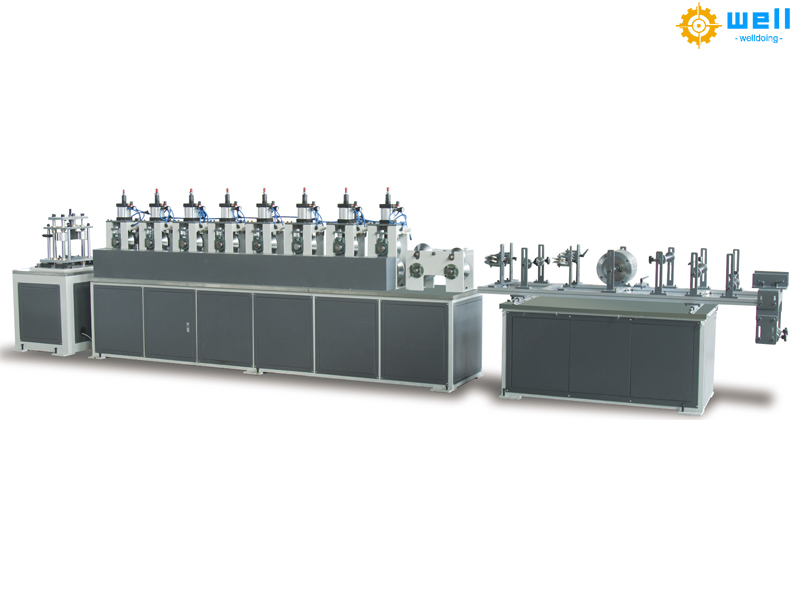

Automation level: Priority should be given to fully automatic or CNC equipment, such as the “100 type paper corner protector production line” which can achieve automatic forming and cutting with high efficiency and small errors.Our company’s CNC multifunctional paper corner protector supports multiple models (L/V/U) and customized sizes, providing greater flexibility.

2. Processing range: The paper edge protector machine needs to be compatible with different widths (30-100mm) and thicknesses (2.5-8mm). For example, our company’s high-speed paper corner protector can produce corner protectors with a width of 20-100mm and a length adjustable to 9000mm.

3. Technical parameters

Production speed: High speed automatic paper corner board making machine can reach 40m/min, while ordinary equipment has a lower speed.

Energy consumption and operation: Equipment with a host power of 7.5kw+4.3kw is more stable and requires 1-2 people to operate.

4. Additional features

Punching and Forming: Equipment with punching function can enhance the practicality of corner protectors.

Drying equipment: If drying and sterilization are required, microwave equipment can be used.

5. Summary and Suggestions

Large scale production: Choose fully automated production lines (such as 100 type or CNC models).

Small and medium-sized: Consider semi-automatic cutting machines or equipment with punching function.

Limited budget: Low priced semi-automatic equipment (such as the 660 yuan model) can meet basic needs.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Oct-20-2025