Welcome to our websites!

News

-

Advantage of Partition Assemble Machine

Automatic partition assembler machine (also known as a rack insertion machine or grid insertion device) is an automated equipment used for warehousing, logistics, or production lines, mainly for the rapid sorting, storage, or handling of goods. Its advantages mainly include the following aspects:...Read more -

Top quality paper corner protection machine

The advantages of paper corner protection production line mainly include the following aspects: High degree of automation: The paper corner forming machine adopts internationally advanced PLC computer programming technology, equipped with automatic clutch, automatic synchronization and automatic ...Read more -

Industrial ink wastewater treatment machine

Industrial ink printing wastewater treatment machine is a comprehensive wastewater treatment system suitable for treating wastewater from small industrial enterprises. Equipment features Highly integrated: integrating various flexo sewage treatment clear equipment processes such as grilles, regu...Read more -

Core purpose of the full automatic carton box folding gluing machine

The full automatic folding gluing machine is an efficient and intelligent packaging equipment, mainly used in the carton forming and processing process, especially suitable for large-scale carton production scenarios. 1. Core purpose Paper box adhesive molding Automatically fold, glue (hot melt o...Read more -

Technology of automatic paper tube making machine

The technical advantages of paper tube making machine are mainly reflected in efficient production, precise control, energy conservation and environmental protection, intelligent operation, and multifunctional adaptability. 1. Efficient production and high production capacity High speed pipe roll...Read more -

Technological development trends of cardboard production line

In recent years, with the tightening of environmental policies, the increasing demand for e-commerce logistics, and the technological upgrading of the packaging industry, the automatic hardboard production line (corrugated cardboard, cardboard, etc.) is developing towards intelligence, efficiency...Read more -

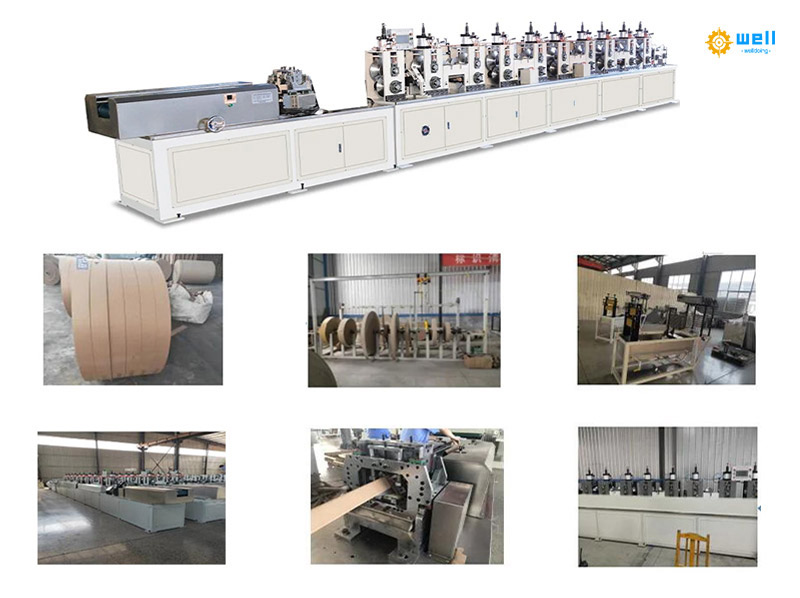

Automatic paper corner protector equipment

paper corner protector machine equipment is a specialized device used for producing paper corner protectors. Working principle Principle of paper corner forming: The paper corner protector machine generally transports multiple layers of paper to the gluing device through a paper guide mechanism. ...Read more -

Design features of the automatic partition assember machine

The working principle of automatic partition assembling machine is mainly based on mechanical transmission and control system. By driving the grid insertion device through the transmission mechanism, the material to be processed is inserted into the grid inside the kiln according to the preset tr...Read more -

Proper using semi-automatic stitching box machine

The semi-automatic carton stitching machine is a widely used nailing equipment for packaging cardboard boxes, cartons, etc. Detailed tutorial on using semi-automatic nail box machine 1. Equipment preparation: Check if the semi-automatic box stitcher machine is intact and if all parts are securely...Read more -

Development process of cardboard ink printing machines

The development process of cardboard flexo printer slotter die cutting machines is closely related to technological progress, and its evolution reflects the continuous improvement of manufacturing automation, environmental protection requirements, and printing accuracy. 1. Traditional printing st...Read more -

flexo ink printing sewage treatment equipment manufacturer

1、 Characteristics of ink wastewater Complex composition: containing pigment particles, organic resins (such as acrylic acid and polyurethane), additives (defoamers and wetting agents), solvents (ethanol, esters), and small amounts of heavy metals (such as lead and chromium). High COD/BOD: High ...Read more -

Automatic grey paper hardboard production line

The grey hardboard production line can composite 2-6 layers of grey cardboard into the required thickness and specifications of hard cardboard. Adopting the composite process of roll paper, automated production is achieved through a production line composed of automatic edge alignment machine, gl...Read more