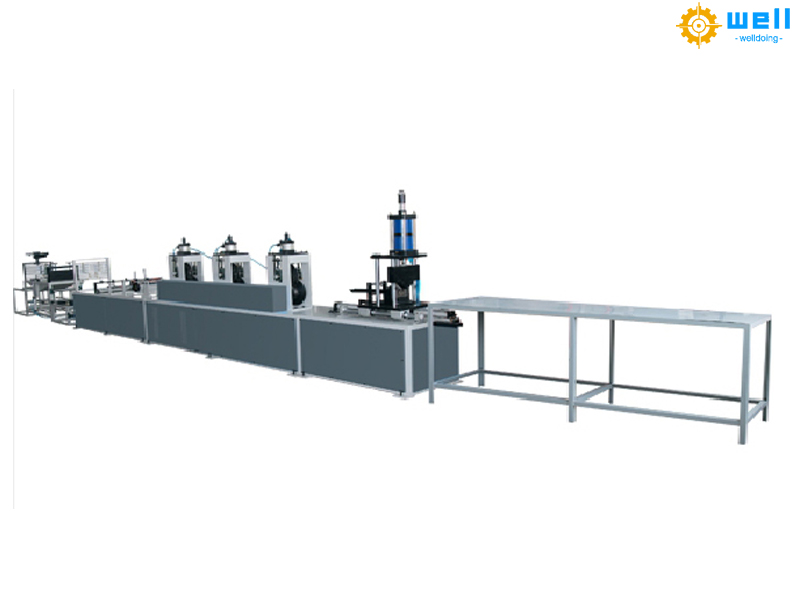

The operation of the paper angle edge board protector needs to be adjusted according to the equipment type (such as production type or packaging type) and functional differences.

1、 Operation process of paper angle edge corner making machine

Raw paper slitting and feeding

Check the status of the slitting equipment, adjust the width of the paper roll according to the product specifications, and install the raw paper roll after slitting onto the paper rack.

Select the quantity of face paper and inner paper according to the thickness requirements to ensure alignment of multiple layers of paper.

Coating and Forming

Adopting a transfer type automatic glue coating, the thickness of the glue layer is adjusted by a scraper, and the pressure of the pressure roller mold needs to be adjusted according to production needs.

Adjust the paper adhesion through the roller set, select the half pack or full pack edge mode, and press it with a roller to form it.

Cutting and Inspection

Synchronize cutting with a CNC cutting machine and set the length through the touch screen to ensure a smooth and burr free cut.

The finished product needs to be checked for surface smoothness, bonding firmness, and printing quality.

2、 Debugging and maintenance for the paper corner protector production line

Recipe switching: Adjust parameters through the touch screen, save and apply different production formulas.

Component correction: Calibrate the position of axes 5-7 to ensure that the wheels are in contact with the frame.Enter the target position data and save it.

Troubleshooting: Regularly check the suction cup, sensor, and pneumatic components to avoid placement failure due to positioning deviation.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Oct-13-2025