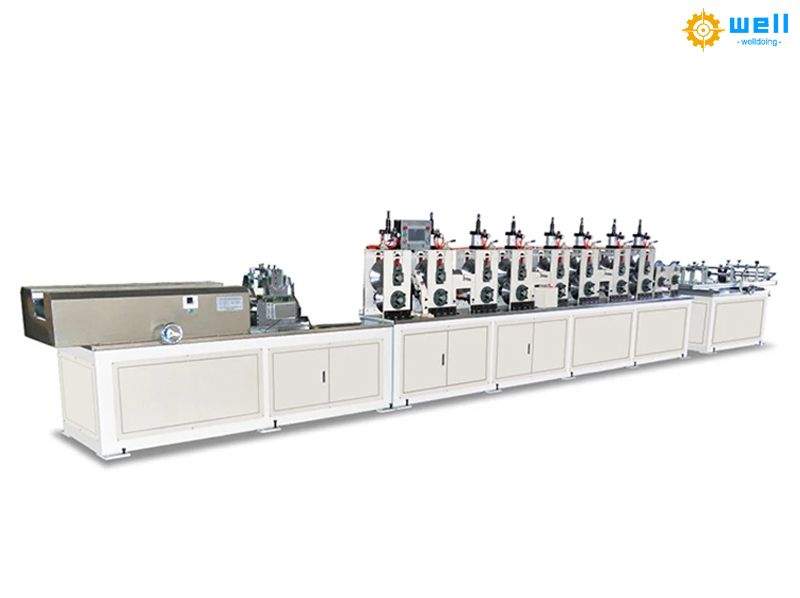

How to adjust the paper corner protector machine equipment correctly

First、 Preparation work before adjusting the corner protector

1. Check the equipment status

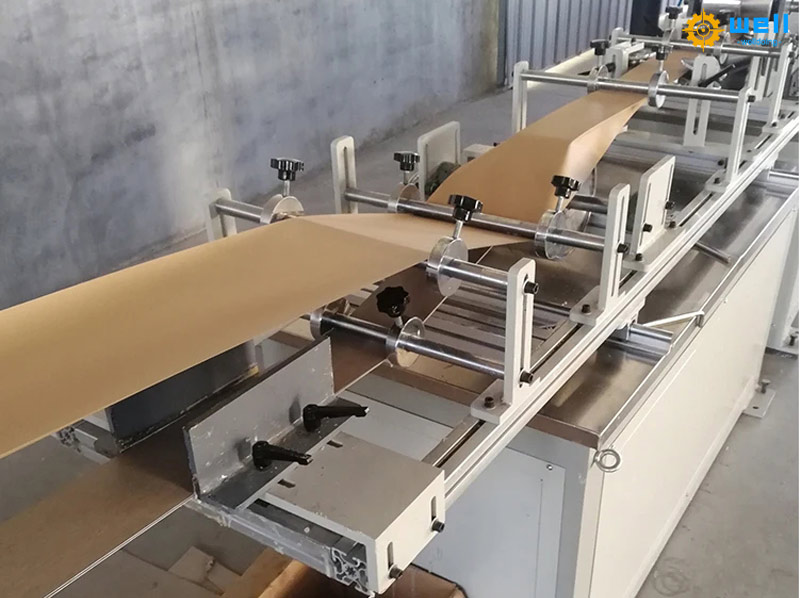

Before adjusting, make sure to disconnect the power supply of the angle machine and clean the dust and debris on the surface of the paper edge protector machine. Check whether each component (such as blades, guide rails, cylinders) is intact to avoid affecting the adjustment effect due to component wear.

2. Prepare tools

Tools such as level gauges, hex wrenches, pressure gauges, etc. need to be prepared.

Second、 Core adjustment steps of paper corner protector machine

1. Horizontal calibration

-Place the level on the workbench and adjust the base screws until the bubble is centered. If the length of the tabletop exceeds 1 meter, it needs to be calibrated in sections with an error controlled within ± 0.1mm.

-Attention: Tilting can cause uneven cutting of corner protectors and even damage to materials.

2. Pressure adjustment

-Set the pressure value based on the material thickness. For example:

-1-3mm gypsum board: air pressure 0.4-0.6MPa (refer to the manufacturer’s technical manual);

-Wooden boards over 5mm: air pressure 0.8-1.0MPa.

-Too low pressure can easily cause corner protectors to fall off, while too high pressure may result in material fracturing.

3. Angle and Position Setting

-Use an angle ruler to adjust the blade angle, and set the conventional right angle guard to 90 °± 0.5 °. If a diagonal angle is required, adjust it according to the design drawings (such as 45 ° or 135 °).

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Nov-11-2025