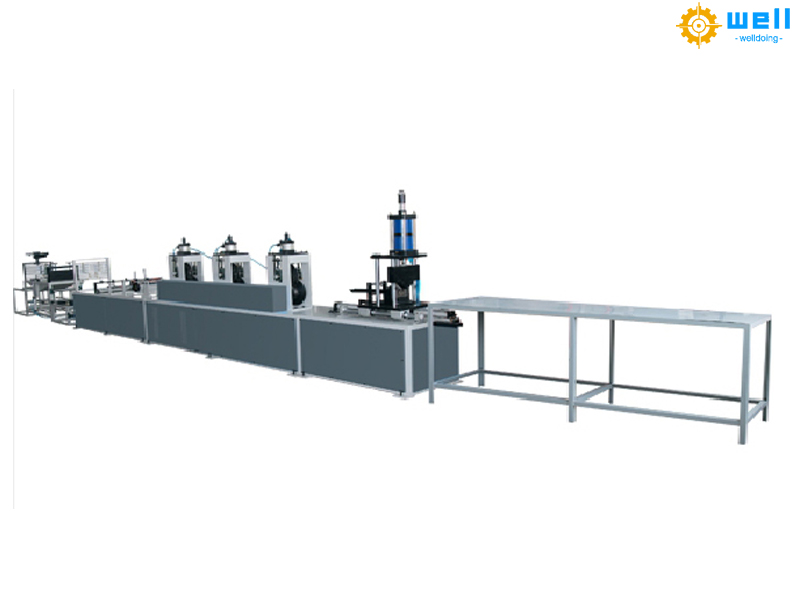

Basic operation process of high-speed CNC paper corner protector machine

1. Power on preparation

-Check if the power supply voltage is stable (usually 380V ± 10%, refer to GB/T 5226.1-2019 standard), and ensure that the automatic angle corner edge protector machine is well grounded.

-Clean the workbench to avoid debris affecting paper feeding.

-Confirm that the lubrication system has sufficient oil (recommended to use ISO VG68 hydraulic oil, which should be replaced every 500 hours).

2. Parameter settings

-Enter the corner guard size, length, and speed through the CNC panel.

-Select the paper type (such as kraft paper, recycled paper), and the system will automatically match the pressing pressure (usually 0.5-1.2 MPa).

3. Production debugging

-First, conduct a no-load test run to observe if all components are functioning properly.

-After inserting the paper, adjust the gap between the rollers (recommended 0.1-0.3mm) to ensure even compression.

2、 Safe operation and common problem handling about paper corner protector production line

1. Safety regulations

-Wear protective gloves during operation to avoid hand contact with cutting blades.

-The emergency stop button must remain in a triggered state (response time ≤ 0.1 seconds).

2. Troubleshooting

-Problem 1: Burrs on the edge of the corner protector

Reason: Blade wear or insufficient pressure.

Solution: Replace the blade (with a lifespan of approximately 80000 cutting cycles) or increase the pressure force by 0.1MPa.

-Problem 2: Paper delivery lag

Reason: The paper is too thick or the rollers are dirty.

Solution: Adjust the paper thickness (≤ 1.5mm) or clean the roller with alcohol.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Oct-16-2025