Paper corner protectors, as a common packaging material, are widely used for edge protection of various products, especially playing an important role in logistics and transportation.

Paper corner protector, as the name suggests, is a corner protector material made from paper, mainly used to reinforce and protect the edges of goods. It is very common in the packaging industry and is favored by many companies due to its environmental friendliness and practicality.

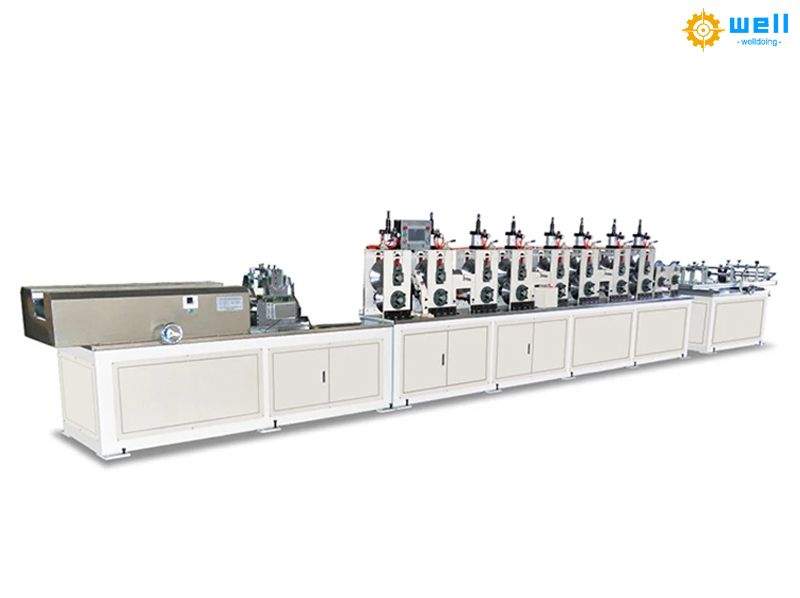

The specific production process of paper corner protector machine equipment

The production of paper corner protectors is a systematic process, and our company has mature technology in this area. The process mainly includes the following steps:

1. Raw material preparation: The main raw materials for producing paper corner protectors are kraft paper or recycled paper, which are reliable sources and meet environmental protection requirements. The company will conduct a preliminary inspection of the paper to ensure that there are no impurities or damages, in order to ensure the quality of subsequent production.

2. Paper processing: After cutting and flattening, the paper will enter the gluing process. The adhesive used for coating is environmentally friendly glue, which is mechanically evenly applied to the surface of the paper to enhance its adhesion and durability.

3. Forming and Pressing: The glued paper will be wound and pressed by a forming machine part of the paper corner protector machine to form an L-shaped or U-shaped corner guard structure. This process requires controlling the pressure and temperature to ensure the stability of the protective angle shape and the neatness of the edges.

4. Drying and curing: The formed paper corner protector will enter the drying chamber and remove excess moisture through natural air drying or low-temperature drying, allowing the adhesive to fully cure. This step is important because it directly affects the strength and durability of the product.

5. Cutting and trimming: The dried corner protectors will be cut according to customer needs to form products of different lengths and specifications. Afterwards, workers will perform manual or mechanical trimming to remove burrs and uneven parts, ensuring a neat appearance.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/WeChat/WhatsApp:+86 13303078975

Post time: Jan-09-2026