The cost savings that can be achieved by using a partition assembler machine for enterprises are mainly reflected in the following aspects:

Labor cost

Reduce manual operation: The cardboard partition assembler inserting machine has a high degree of automation and can replace a large amount of manual grid inserting work. The grid insertion task, which originally required multiple people to complete, now only requires a small number of personnel to operate and monitor after using the machine, significantly reducing labor costs.

Improve production efficiency: Machine grid insertion speed far exceeds manual labor, and can complete more workload in the same time, enabling enterprises to produce more products when manpower is limited, indirectly saving labor costs.

Material cost

Reduce material waste: The full automatic partition assembler machine inserts grids accurately, ensuring accurate size and position of each grid, reducing material waste caused by manual operation errors, improving material utilization, and saving raw material procurement costs.

Optimize material selection: Some partition inserting machines can handle various types and thicknesses of cardboard, allowing enterprises to flexibly choose suitable materials according to product needs, avoiding excessive use of high-quality and high cost materials, and further reducing material costs.

Equipment cost

Multi functional applications: Some cardboard partition assembler machines have multiple functions, such as the ability to perform grid insertion and cutting operations simultaneously, reducing the dependence of enterprises on other equipment and lowering equipment procurement and maintenance costs.

Long term stability: The high-quality partition assembler machine has a reasonable structural design, high component quality, low failure rate, low maintenance cost, and can operate stably for a long time, saving equipment replacement and maintenance costs for enterprises.

Time cost

Improve production efficiency: The paper cardboard automatic partition assembly machine operates at high speed and can complete a large number of grid insertion tasks in a short period of time, shortening the production cycle of the enterprise, responding to market demand faster, improving capital turnover, and saving time costs.

Reduce production delays: The machine runs stably and is less affected by external factors, effectively avoiding production delays caused by artificial fatigue, emotions, and other factors, ensuring production progress.

Quality cost

Improving product quality: The partition assembler machine has good grid inserting quality, with a smooth and wrinkle free surface, reducing returns and rework caused by quality issues, and lowering quality costs.

Enhance corporate reputation: High quality products can enhance corporate reputation and market competitiveness, attract more customers, and bring more business and profits to the enterprise.

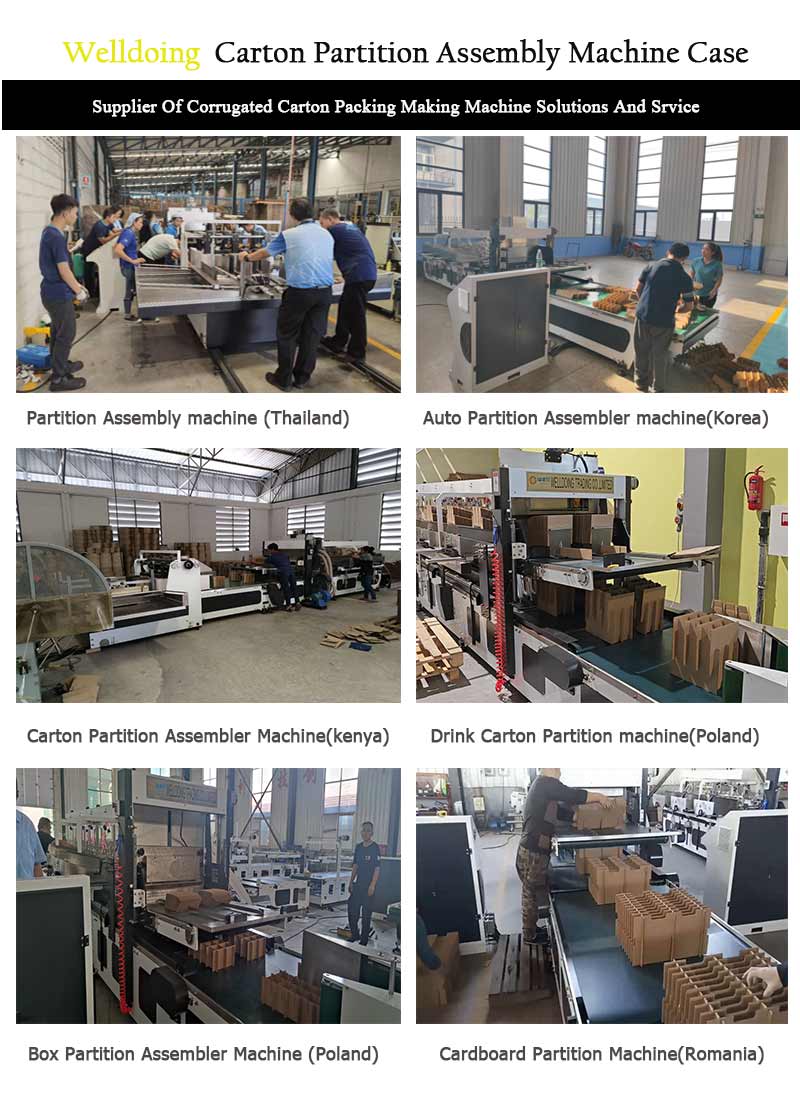

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: May-07-2025