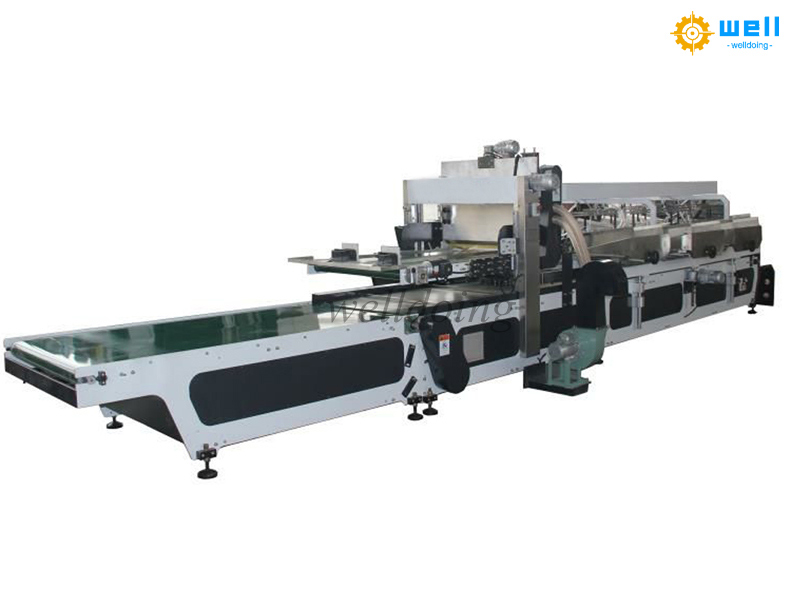

A packaging partition assembly machine is an automated device specifically designed for making cardboard partition slotting (such as gift box liners, electronic product packaging trays, etc.). By accurately cutting and folding cardboard, customized honeycomb or independent grid structures are formed to protect items from collisions during transportation and storage.

1. automatic partition assembler insert machine functions and purposes

Core functions

Automatic cutting: Cutting cardboard with a knife or laser to create preset slot cuts.

Precise folding: Fold the cut cardboard into a three-dimensional partition structure (such as a nine grid, honeycomb grid, etc.) according to the design.

Efficient molding: suitable for materials such as grey board paper and corrugated paper with different thicknesses (usually 0.5-3mm).

Typical application scenarios

Luxury packaging (jewelry, wine gift box lining).

Electronic products (such as mobile phones, cameras, etc.) with shock-absorbing mounts.

Logistics transportation (multiple items are packed in compartments to avoid collision with each other).

2. Technical features and advantages

High precision and consistency: The error can be controlled within ± 0.2mm to ensure perfect matching between the grid and the product. Strong stability in repeated production, suitable for standardized packaging requirements.

Flexibility and customization: Quickly switch between different grid designs by changing the cutting die or adjusting the program. Support CAD file import, suitable for small batch customized orders.

Efficient and energy-saving: With a high degree of automation, it can process 20-50 pieces per minute (depending on complexity). Some models are equipped with an automatic waste recycling system to reduce material waste.

3. Operation and maintenance suggestions for cardboard partition inserting machine

Operation standard: Regularly calibrate cutting and folding units to avoid deviation accumulation. Adjust the pressure according to the characteristics of the cardboard (such as corrugated paper requiring anti crushing).

Maintenance points: Clean the blade/laser head to prevent paper scraps from accumulating and affecting accuracy. Lubricate moving parts such as rails and cylinders to extend their lifespan.

The cardboard grid inserting machine is a key equipment in the packaging industry to improve product protection and aesthetics. With the increasing demand for personalized packaging and e-commerce logistics, its market potential is significant. The future development direction will focus on intelligent, flexible production, and adaptation of green materials, while reducing the barriers to entry for small and medium-sized enterprises.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jun-10-2025