The advantages of ink printing wastewater treatment machine include:

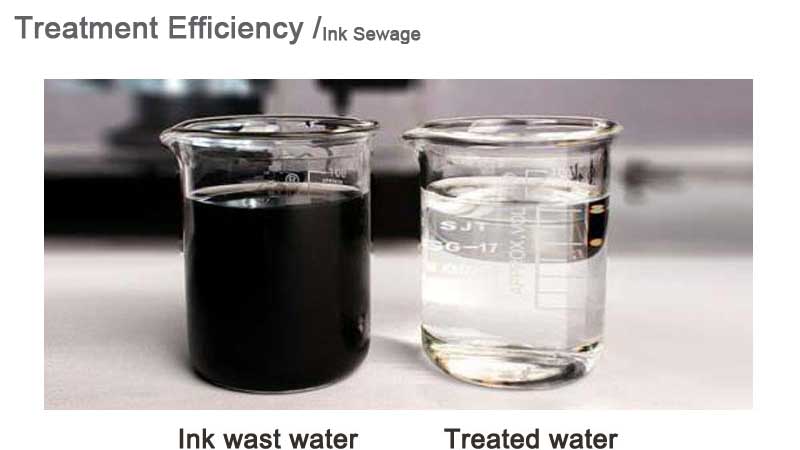

High pollution removal: It can effectively remove organic matter, pigments, and suspended solids from sewage, significantly reducing the concentration of pollutants.

Water resource recycling: The treated water can be reused, reducing the water cost for enterprises and promoting resource recycling.

Environmental compliance: Help enterprises comply with environmental regulations, reduce environmental pollution risks, and protect the ecological environment.

Automated operation: ink printing wastewater treatment equipment equipped with an automatic control system to simplify the operation process, improve work efficiency and safety.

Sludge reduction: Adopting advanced technology to reduce sludge production and lower the cost of post-treatment and disposal.

Strong adaptability: able to adjust according to different sewage characteristics and flexibly respond to treatment needs.

Anti Du and anti Jun functions: Optional anti Du process can be configured to ensure the safety of effluent water quality and prevent secondary pollution.

Economic benefits: Although the initial investment is relatively high, good economic returns can be achieved by saving water and processing costs.

These advantages make Industrial Waste Water Treatment Process play an important role in the industry, helping companies achieve sustainable development goals.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Dec-15-2025