Welcome to our websites!

News

-

Paper Tube Making Machine Special Features

The paper tube making machine can produce thousands of high-precision paper tubes per hour through automated winding, bonding, drying, and cutting technologies, which is more than 10 times more efficient than manual production and reduces costs by 30%. It is the preferred solution for environment...Read more -

Optimizing the efficiency of the hardboard production line

Optimizing the efficiency of the automatic hardboard production line requires comprehensive improvement from multiple dimensions such as equipment, process, and management, combined with industry practice and technological trends. Specific measures are as follows: 1、 Equipment and process optimi...Read more -

Kraft paper angle board guard protector machine

The operation of the paper angle edge board protector needs to be adjusted according to the equipment type (such as production type or packaging type) and functional differences. 1、 Operation process of paper angle edge corner making machine Raw paper slitting and feeding Check the status of the...Read more -

safe operation of automatic folder gluer carton box machine

automatic folder gluer machine is an automated equipment used for packaging boxes, widely used in logistics, packaging and other industries. It is necessary to establish a set of operating procedures for the gluing machine to ensure its safe operation and efficient production. Pre-operation prepa...Read more -

Methods of choosing a suitable sewage treatment machine

In the context of increasingly strict environmental requirements, it is crucial to choose appropriate sewage treatment equipment. We provide you with a professional selection guide from four aspects: requirements analysis, equipment performance, material construction, and operating costs. 1、 Req...Read more -

Automatic spiral paper tube making machine

Spiral paper core making machine is an industrial equipment for producing paper tubes. The equipment uses a rotating core shaft to spiral wrap paper strips to form continuous paper tubes. The production process includes cutting, gluing and rolling tubes, drying, and precision cutting. Steps for u...Read more -

Regular maintenance of cardboard partition assembler machine

The full automatic partition assembler machine is a device used for producing cardboard grids. In order to ensure its normal operation and extend its service life, regular maintenance is required. Regular maintenance of cardboard partition assembler machine 1. Replace vulnerable parts: According ...Read more -

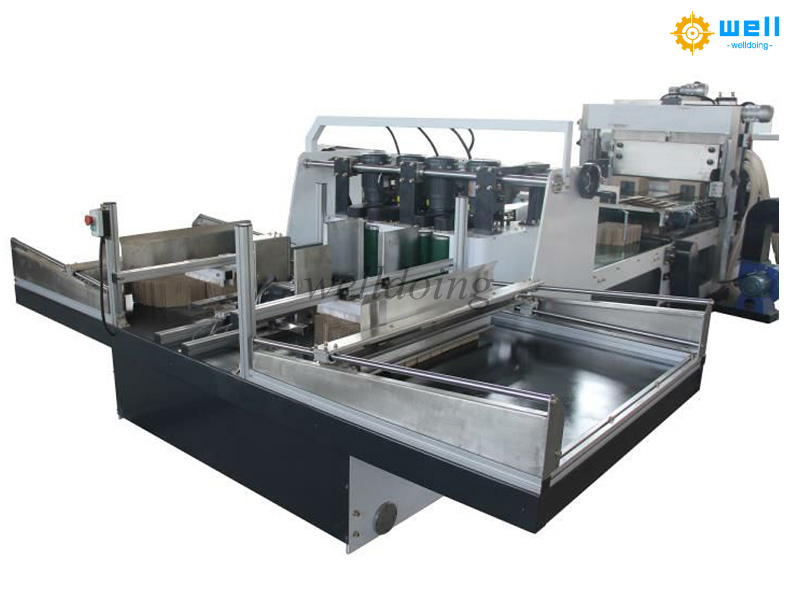

Cardboard flexo ink printing slotting die cutting machine

A cardboard printing slotting die cutting machine is a specialized equipment that prints text, patterns, and information onto the surface of a cardboard box. It mainly achieves printing functions through processes such as plate loading, ink coating, embossing, and paper feeding. When the automati...Read more -

Development Analysis of Grey Hardboard Production Line

Development Analysis of grey hardboard production line 1. Upgrading high-strength and lightweight technology Grey cardboard, as an important material in the packaging industry, will develop towards high strength and lightweight in the future. By optimizing the fiber ratio and process technology, ...Read more -

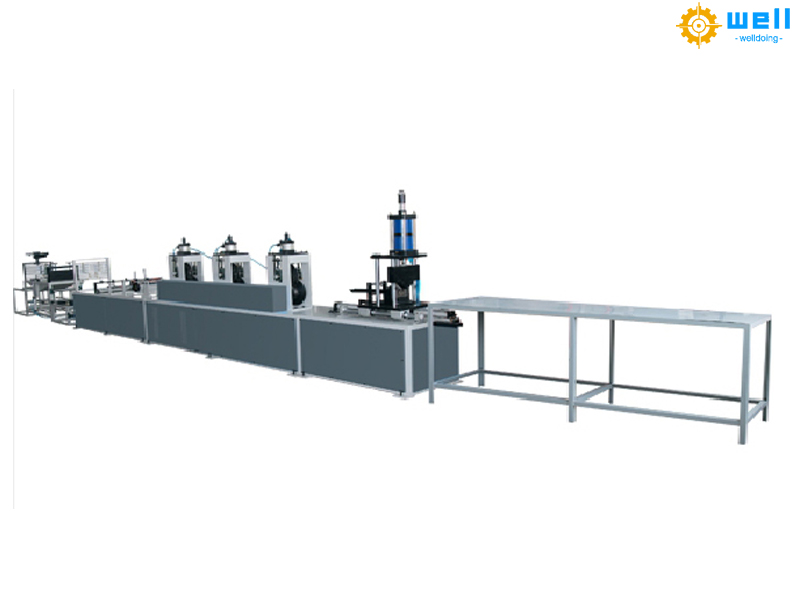

Automatic paper corner protector production line

The operation requirements of the paper angle edge board protector need to be combined with equipment characteristics and safety regulations. 1、 Preparation before operation Equipment inspection: Confirm that the slitting machine, glue coating machine, roller mold and other components are intact...Read more -

Operating precautions of the partition assembly inserting machine

The operating precautions of the cardboard automatic partition assembler insert machinery mainly include the following aspects: 1、 Safety operation standards Personnel training: Operators need to receive professional training, be familiar with equipment processes and safety regulations, and are ...Read more -

Operation technology of paper tube making machine

The operation technology of automatic paper tube equipment involves equipment control, process parameter adjustment, and safety regulations. 1、 Fundamentals of Equipment Operation Control system Adopting CNC computer numerical control system and Delta PLC control, supporting HMI touch screen int...Read more