Welcome to our websites!

News

-

Principle of sewage treatment equipment

ink wastewater treatment system is a device used to treat various types of wastewater, widely used in industries, cities, and agriculture. Wastewater treatment equipment can remove harmful substances from wastewater through various principles and technologies to achieve the goal of purifying wate...Read more -

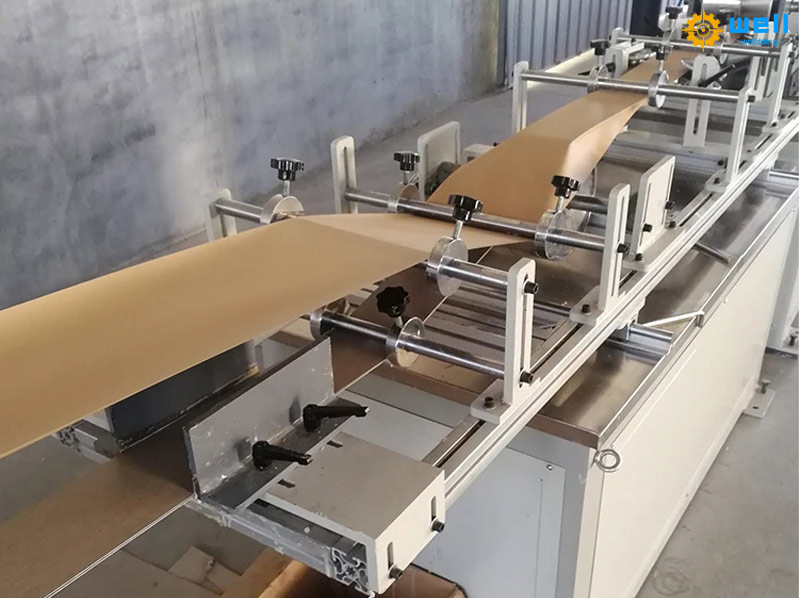

Semi automatic cardboard box stitching machine

Working principle of semi-automatic stitching machine The semi-automatic stitching box machine adopts pneumatic or electric drive, and achieves automatic operation of the stitch box through a precise control system. The working principle mainly includes the following steps: firstly, place the car...Read more -

Safety assurance measures for partition assembler machine

Safety assurance measures for partition assembler machine 1. Establish a sound construction safety management system. According to the principle of “safety must be managed in production”, part-time safety officers are appointed for each sub project, and safety managers are appo...Read more -

Process and technical characteristics of paper tube machine

The paper tube machine, as a specialized machine equipment for producing paper tubes, exhibits diverse characteristics in terms of process methods and technical features. From the perspective of production methods, paper tube machines are mainly divided into spiral winding machines, flat winding ...Read more -

Automatic paper corner forming protector machine

paper corner protector machine equipment refers to a specialized machine for producing paper corner protectors. It is generally composed of devices such as paper guide, gluing, forming, cutting, automatic stacking, and some accessories, and can complete all the processes of paper corner protector...Read more -

Inspection of the fully automatic cardboard production line

The inspection of the fully automatic hardboard production line involves multiple key links to ensure that the product quality meets the standards. The following are the main testing items and related equipment of hardboard making machine: 1. Thickness detection Equipment: Thickness detection dev...Read more -

Fully automatic flexo printer slotter die cutting machine

In the increasingly competitive packaging industry, improving production efficiency and reducing costs have become the key to the survival of enterprises. The fully automatic flexo printer slotter die cutting machine, with its intelligent operation process and strong production capacity, is becom...Read more -

Application analysis of integrated wastewater treatment equipment

Integrated waste water treatment machine, as an advanced device that integrates wastewater collection, pretreatment, biological treatment, deep purification, and disinfection, achieves efficient purification of wastewater through a series of complex process steps to meet discharge or reuse standa...Read more -

Automatic carton partition assembling machine

As a highly automated device, the carton partition assembling machine plays an important role in industrial production. It is mainly used to insert materials into grids according to certain specifications, achieving fast and accurate positioning and arrangement. The working principle of the grid ...Read more -

Automatic Spiral Paper Tube Production Line

The Automatic Spiral Paper Tube Production Line can produce thousands of high-precision paper tubes per hour through automated winding, bonding, drying, and cutting technologies, which is more than 10 times more efficient than manual production and reduces costs by 30%. It is the preferred soluti...Read more -

Automatic grey hardboard production line

The automatic hardboard production line in cardboard packaging enterprises, including wet end equipment, cadre equipment, production management system and several other important components Wet end equipment configuration The wet end equipment is the key equipment for corrugated forming in the en...Read more -

How to adjust the paper corner protector machine correctly ?

How to adjust the paper corner protector machine equipment correctly First、 Preparation work before adjusting the corner protector 1. Check the equipment status Before adjusting, make sure to disconnect the power supply of the angle machine and clean the dust and debris on the surface of the pap...Read more