Welcome to our websites!

News

-

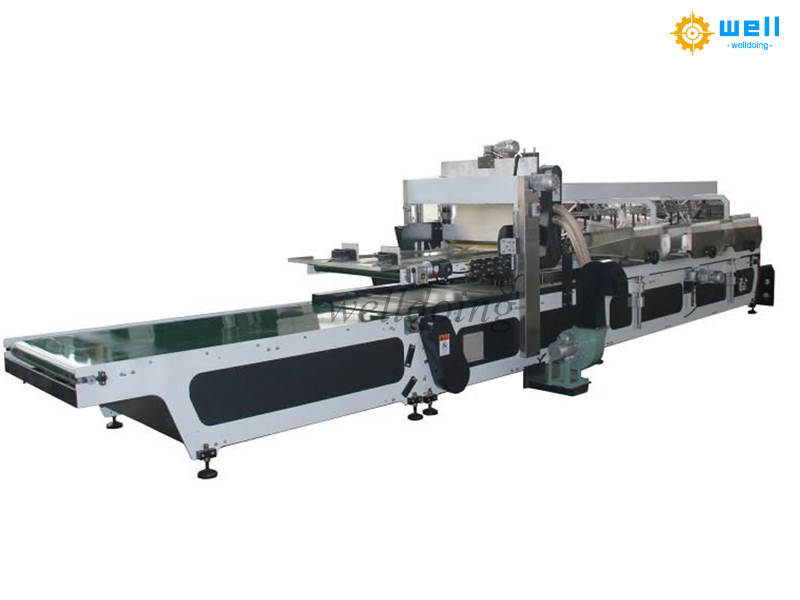

corrugated carton stitching machine

Automatic corrugated carton stitching machine is mainly used for carton production, and can also be used for other types of box assembly. It can be used in food, beverage, tobacco, cosmetics, medicine, electronics, daily necessities and other industries, so as to improve the quality of box assemb...Read more -

High speed ink printing machine

The automatic flexo printing die cutting slotting machine is designed specifically for water-based ink printing, which is environmentally friendly, user-friendly, easy to operate, quick to change orders, and high-speed processing and production. Adopting full computer control, with a high degree ...Read more -

How to choose a suitable automatic partition assembly machine?

How to choose a suitable automatic partition assembler insert machine? 1. Usually, companies planning to purchase automatic locking screw equipment hope to use automation equipment as soon as possible to improve efficiency and save manpower. However, generally, there is no manufacturer of automat...Read more -

The powerful performance of ink printing die cutting machine

Regarding the powerful performance of automatic flexo printer die cutter slotter machine, different companies have different opinions. Users may need to know more about the performance characteristics of water ink printing die cutting machines. Therefore, today, Dongguang Evergrande Packaging Mac...Read more -

Key points for using semi-automatic box stitching machine

With the continuous development of packaging technology, we have also seen that the requirements for the appearance of corrugated boxes are increasingly high, such as exquisite printing patterns, neat and beautiful nail line sealing, etc. If we use a semi-automatic stitching machine at this time,...Read more -

Maintenance of flexo printing slotting die cutting machine

automatic flexo printing die cutting slotting machine is an imaging technology that does not require an image carrier. It uses small functional components and short paths to directly print ink on the substrate based on the information to be printed. It has advantages such as wide application fiel...Read more -

Characteristics of high-speed ink printing machine

Nowadays, packaging companies generally use printing machines, and the probability of using ink printing machines is higher. So, do you know about high speed ink printing machines? What are the main characteristics of high-speed ink printing machines? The entire machine is designed and manufactur...Read more -

How to distinguish the quality of the EPE foam sheet

Our company is a professional manufacturer of complete sets of equipment such as EPE foam sheet machine, EPE foaming tube making machine, EPE foam fruit net making machine , EPE foam rod (special-shaped) machine and EPE foam units. With a development history of over 20 years, we are a plastic mac...Read more -

The difference between automatic and semi-automatic box stitching machines

The demand for products is high, and the types of production machinery are also increasing. There are three main types of automatic stitching machines in the box nailing machine industry, including semi-automatic box nailing machines, fully automatic box nailing machines, and double sheet box nai...Read more -

How to choose a high-quality semi-automatic box nailing machine

In recent years, the importance of semi-automatic box nailing machines in the market has gradually increased. Packaging machinery manufacturers have begun the development phase of nail box machines in response to this prospect. After the production of semi-automatic box nailing machines and their...Read more -

Operation of the partition assembly machine

We can take a look at whether the appearance certificate and operating machinery certificate of the equipment are complete before entering the site, to ensure that there are no dangerous fevers during the construction process. Also, debugging should be carried out before use to ensure the perform...Read more -

Functions of fully automatic ink printing machine

Functions of fully automatic flexo printing die cutting slotting machine This machine consists of five parts: paper feeding, printing, slotting, die-cutting, and palletizing. The feeding part adopts the leading edge feeding method. Equipped with a high-pressure vacuum device, it can remove impuri...Read more