In the context of increasingly strict environmental requirements, it is crucial to choose appropriate sewage treatment equipment. We provide you with a professional selection guide from four aspects: requirements analysis, equipment performance, material construction, and operating costs.

1、 Requirement analysis

Firstly, it is necessary to clarify the source and nature of the wastewater. Domestic sewage is rich in organic matter, nitrogen and phosphorus, while industrial sewage may contain heavy metals, toxic substances, etc. By detecting the acidity and alkalinity of wastewater COD、BOD、 The appropriate treatment process and equipment type can be determined based on indicators such as ammonia nitrogen content. At the same time, clarifying the water quality standards after treatment, such as discharge standards or reuse standards, has guiding significance for equipment selection.

2、 Equipment performance

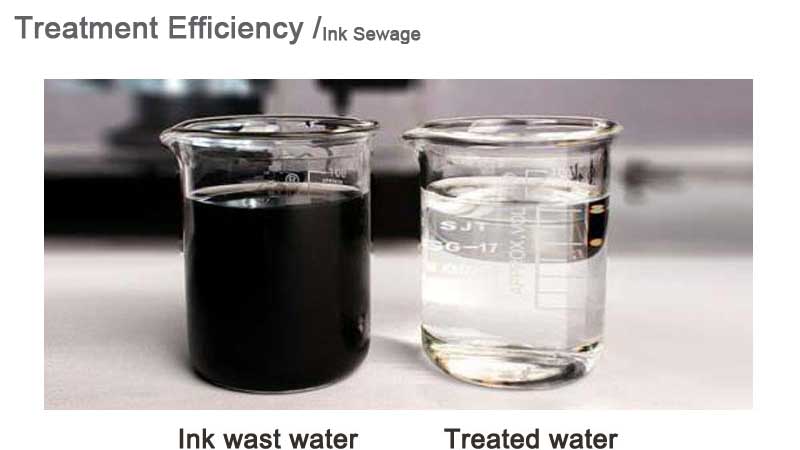

Processing efficiency: Efficient ink sewage treatment clear equipment can process a large amount of sewage in a short period of time, meeting practical needs. For example, advanced biological treatment equipment can quickly decompose organic matter and improve removal efficiency by optimizing the microbial community.

Stability: The stability of a device determines its long-term operational reliability. Choosing equipment that has been verified through practice and has mature design and manufacturing processes can ensure stable operation under different working conditions.

Automation level: Automated equipment can achieve functions such as automatic dosing, monitoring, and control of operating parameters, reducing manpower input and improving the stability of processing efficiency.

3、 Material Structure

Material: The material of the equipment directly affects its service life and corrosion resistance. For components that come into contact with sewage, corrosion-resistant materials such as stainless steel, fiberglass, etc. should be selected.

Construction design: Reasonable construction design helps improve the processing efficiency and maintenance convenience of equipment. Modular design facilitates installation, disassembly, and maintenance; The internal water flow channel is designed reasonably to ensure uniform flow of sewage and improve treatment efficiency.

4、 Operating costs

Energy consumption: Choosing energy-saving industrial wastewater treatment machine can reduce operating costs. For example, biological treatment equipment using advanced aeration technology can automatically adjust the aeration amount according to actual needs, reducing energy waste.

Drug consumption: Understanding the drug consumption of the equipment and selecting equipment with low drug consumption and good treatment effect can reduce the cost of drug procurement.

Maintenance cost: Choosing equipment that is easy to maintain and has easily accessible components can reduce maintenance costs. At the same time, paying attention to the manufacturer’s after-sales service, such as regular inspections, technical support, etc., can reduce maintenance concerns.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Oct-11-2025