1.flexo ink printing sewage treatment equipment cleaning

Regularly clean the surface oil and dust of the equipment to prevent blockage or corrosion.

Promptly remove ink residue from the grille and filter screen to avoid clogging and affecting water flow.

Check whether there are leaks in the pipelines and valves, and whether the seals (such as O-rings and gaskets) are aging.

Operation monitoring

Record the quality of incoming and outgoing water (COD, chromaticity, pH, etc.), and adjust the process promptly if any abnormalities are found.

Observe whether the equipment operates with normal noise and vibration, and whether the motor/pump is overheated.

Pharmaceutical management

Check the remaining amount of coagulants, pH adjusters, and other agents to avoid any interruption that may affect the treatment effect.

Regularly clean the dosing device to prevent crystallization or blockage.

2、 Regular maintenance

Mechanical components

Pumps: Check the lubrication condition of bearings every month and replace lubricating oil; Clean the debris from the impeller.

Blender: Check for blade deformation and motor insulation performance.

Fan: Clean the air filter and check the tightness of the belt (if any).

Filtration system

Backwash filter materials (such as activated carbon and quartz sand) should be replaced in a timely manner according to the pressure difference.

Check the contamination of membrane components (such as ultrafiltration/reverse osmosis membranes) and clean them chemically according to the manufacturer’s recommendations.

electrical system

Check whether the control cabinet wiring and PLC module are damp or dusty, and tighten the wiring terminals.

Test the accuracy of sensors (such as pH meters and flow meters) and calibrate them regularly.

Sludge treatment unit

Clean the filter cloth of the sludge concentration tank or filter press to prevent compaction.

Check the wear and tear of the sludge pump and replace vulnerable parts in a timely manner.

3、 Seasonal maintenance

Winter: Anti freezing measures (such as adding insulation layer and draining pipelines to store water).

Rainy season: Check the grounding and lightning protection of equipment to avoid moisture and short circuits in the circuit.

if you need this equipment,please see below

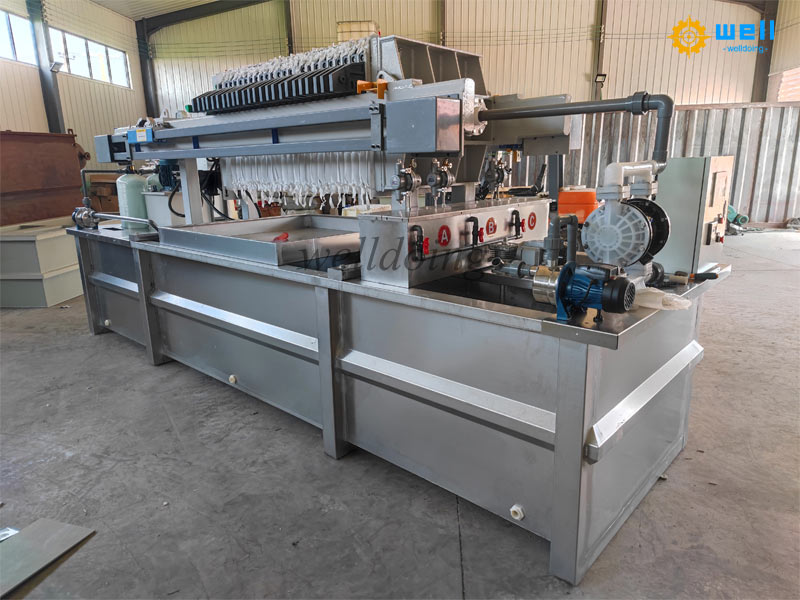

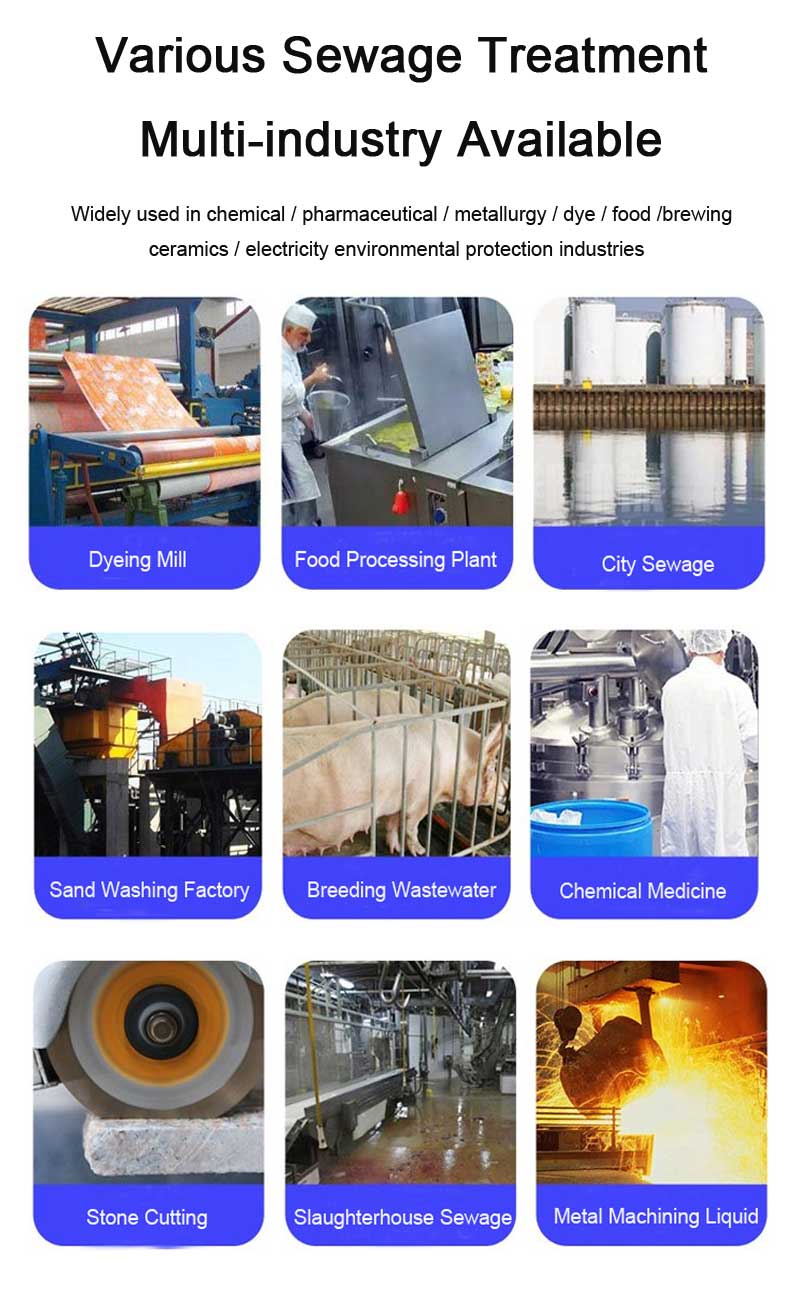

flexographic ink printing sewage treatment machine:

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jun-09-2025