Intelligent ink sewage treatment clear equipment is an efficient solution developed for the treatment needs of decentralized sewage (such as rural areas, scenic spots, service areas, small communities, homestays, etc.). Its core advantage lies in highly integrating, automating, and intelligentizing traditional sewage treatment processes.

1. Highly integrated and modular, small footprint, flexible deployment

Integrated design: Integrating multiple units such as pretreatment, biochemical treatment (such as A/O, MBBR, MBR), sedimentation, disinfection, etc. into one tank or container, with a compact structure.

Modular assembly: Modular combination can be carried out according to the processing water volume (usually ranging from a few tons to several hundred tons per day), making expansion convenient.

Strong adaptability: Suitable for areas with complex terrain and uncovered pipelines, it can be installed above or underground, saving land and having minimal impact on the surrounding environment.

2. Highly automated and intelligent, achieving “unmanned operation”

This is its most prominent feature.

Fully automatic operation: Through the PLC intelligent controller, the start and stop of the water pump, fan, dosing pump, and disinfection device are automatically controlled, achieving 24-hour unmanned operation.

Intelligent aeration and energy saving: using dissolved oxygen (DO) online monitoring+frequency conversion control, adjusting the aeration amount in real time according to water quality, avoiding excessive aeration, and saving up to 30% -50% energy.

Intelligent dosing: Based on water quality (such as pH, turbidity) or treatment stage, automatically and accurately add disinfectants (such as sodium hypochlorite), carbon sources, etc. to ensure effectiveness and reduce drug consumption.

Fault self diagnosis and alarm: The ink printing wastewater treatment machine has functions such as liquid level alarm, equipment fault alarm, water quality abnormality alarm, etc., and is pushed to management personnel in real time through SMS, APP or cloud platform.

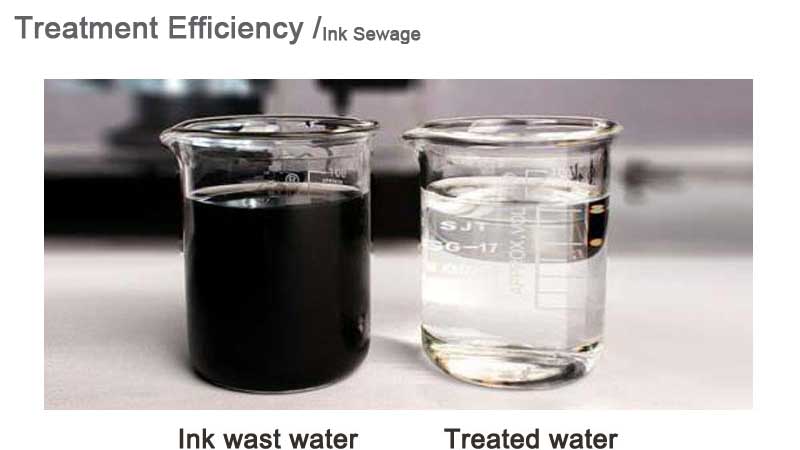

3. High processing efficiency and stable effluent quality

Efficient core processes: Advanced processes such as membrane bioreactor (MBR), moving bed biofilm (MBBR), and high-efficiency biofilter are commonly used, resulting in high sludge concentration and pollutant removal efficiency far exceeding traditional methods.

High effluent standards: The effluent quality can stably meet the Class A standard of the “Pollutant Discharge Standards for Urban Sewage Treatment Plants” or stricter local standards, and can even be directly used for greening, flushing, and other reuse purposes.

Strong resistance to impact loads: The intelligent system can sense changes in water inflow and quality, automatically adjust operating parameters, and ensure stable operation during peak water usage or water quality fluctuations.

4. Easy operation and controllable cost

Significantly reduce labor costs: No need for dedicated personnel to guard the site, regular inspections and maintenance are sufficient.

Intelligent maintenance reminder: The Industrial Waste Water Treatment Process will automatically prompt maintenance tasks, such as cleaning membrane components, adding chemicals, replacing filter materials, etc.

Low sludge production: Due to the use of efficient biochemical processes, the sludge age is long and the sludge yield is low, reducing the frequency and cost of cleaning and treatment.

5. Outstanding ecological and environmental benefits

Source control: Achieve on-site collection, treatment, and reuse/standard discharge of sewage to prevent the formation of black and odorous water bodies.

Resource utilization: Standard effluent can be used for landscape water replenishment, agricultural irrigation, municipal miscellaneous use, etc., promoting water resource cycling.

Environmentally friendly: The upper part of the buried equipment can be covered with soil for greening, beautifying the environment; Fully enclosed design, effectively preventing odor and noise pollution.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/WeChat/WhatsApp:+86 13303078975

Post time: Jan-14-2026