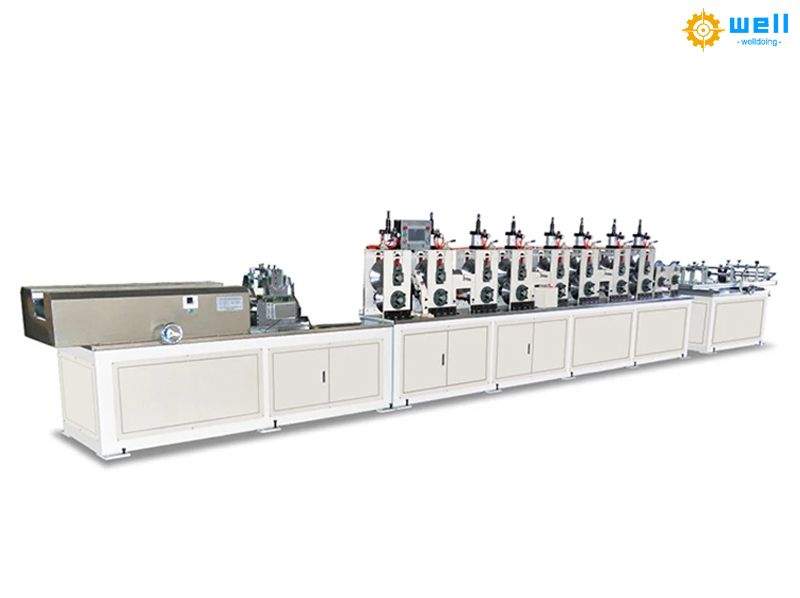

The Kraft paper corner protector production equipment efficiently converts paper into high-strength corner protectors through automated processes.

Core process flow

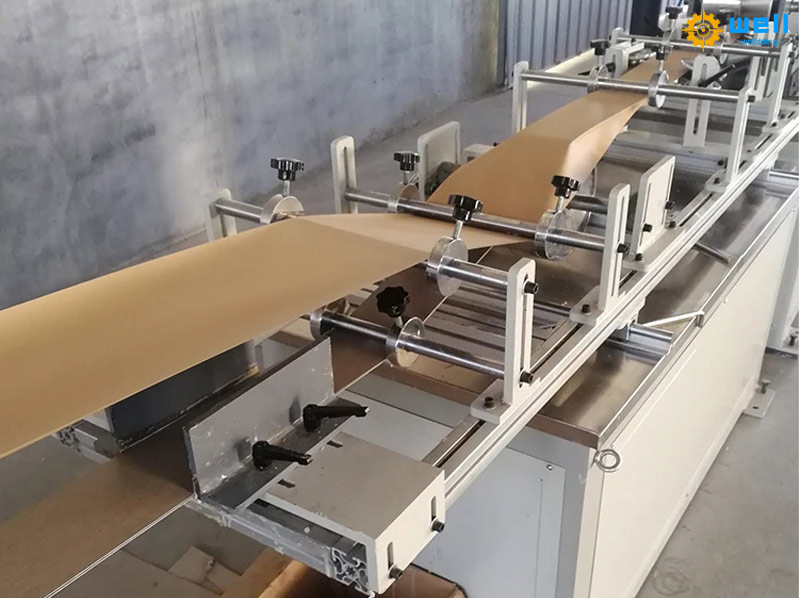

Raw material preparation: Beef card noodle paper and sand tube paper are stacked in proportion and automatically glued using a pneumatic diaphragm pump.

Forming and shaping: Eight sets of pressure roller pneumatic lifting adjustment, servo motor driven cutting and punching angle to ensure dimensional accuracy.

Material receiving system: automatic counting and fault alarm, supporting continuous material receiving.

In order to extend the service life of paper corner protectors, regular maintenance, standardized operation, and timely replacement of vulnerable parts must be carried out.

1、 Core maintenance measures

Lubrication system: Check the lubricating oil level weekly to ensure that the lubricating grease reaches all parts. Regularly replace lubricating oil to avoid the deterioration of oil quality affecting equipment efficiency.

Component fastening: Check the looseness of screws every month and tighten them in a timely manner. High speed rotating components need to be carefully inspected to prevent vibration and noise.

Cleaning and maintenance: Clean the paper angle edge corner making machine surface and ventilation ducts weekly. Regularly clean the cooling device and replace the coolant.

Electrical system: Check the aging condition of cables every month to ensure that sensors are working properly. Regularly clean electrical components of oil and dust.

2、 Operating standards

Fixed personnel and fixed equipment: Adhere to the operation of fixed personnel and fixed equipment, and follow the operating procedures.

Reasonable use: Avoid overloading and prevent equipment damage.

3、 Replacement of vulnerable parts

Regular replacement: According to the usage of the equipment, replace vulnerable parts (such as pressure rollers and cutting devices) regularly.

Timely repair: Discover faults and repair them promptly to prevent minor issues from escalating.

4、 Professional maintenance

Minor repair: The paper angle board protector machine has been running for 2500 hours and requires a minor repair to replace vulnerable parts and restore accuracy.

Overhaul: Regularly conduct major repairs based on the service life of the equipment and comprehensively inspect its condition.

Through the above measures, the service life of paper corner protectors can be effectively extended and maintenance costs can be reduced.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/WeChat/WhatsApp:+86 13303078975

Post time: Dec-31-2025