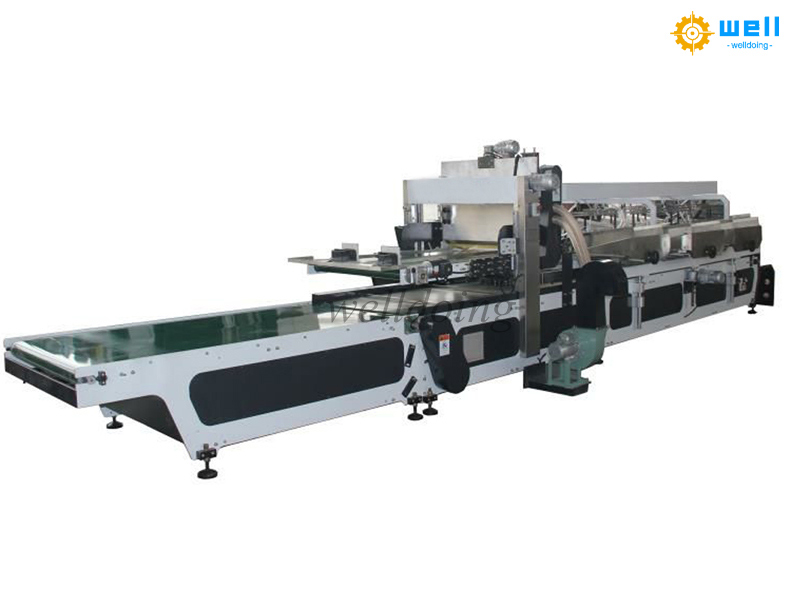

The installation of the packaging partition assembly machine (equipment used for making cardboard partitions, display racks, and other products) must comply with the following technical requirements to ensure stable operation and production safety of the equipment:

1、 Basic environmental requirements

Site conditions: The ground is flat and sturdy (concrete hardened ground is recommended), and the load-bearing capacity needs to meet the weight of equipment and materials (usually ≥ 5 tons/square meter). The installation area should be free of vibration sources, dust, and corrosive gases, and should avoid high temperatures and humidity (temperature 5-40 ℃, humidity ≤ 70%). Reserve 1-1.5 meters of operating space around the equipment for easy maintenance and loading.

Power supply: The voltage is stable and meets the nominal voltage of the equipment (commonly 380V three-phase or 220V single-phase), with a fluctuation range of ± 10%. Independent distribution box, equipped with overload protection device, grounding resistance ≤ 4 Ω. The specifications of the power cord need to match the power of the equipment (for example, for 5kW equipment, it is recommended to use copper core wires of 4mm ² or more).

Air source requirements (for pneumatic models): Compressed air pressure of 0.6-0.8MPa, flow rate ≥ 0.3m ³/min, equipped with oil-water separator and pressure stabilizing device. The pressure resistance of the trachea is ≥ 1MPa, and the interface uses quick plug or threaded sealing.

2、 Equipment installation steps

Positioning and leveling: Use a laser level to calibrate the automatic carton partition assembler machine base, with a levelness error of ≤ 0.1mm/m, and fix it with anchor bolts. The machine model with conveyor belt needs to adjust the parallelism of the conveyor belt, with a deviation of ≤ 2mm.

Mechanical component assembly: Install the mold, cutter, and grid mechanism according to the instructions, ensuring that the bolt torque of each component meets the standard (such as M12 bolt torque is usually 80N · m). Check the lubrication condition of the guide rail and slider, and apply lithium based grease (NLGI grade 2).

Electrical and control system: Servo motor/stepper motor cables need to be shielded and laid away from power lines (spacing ≥ 30cm). Touch screen or PLC control cabinet should be dust-proof and moisture-proof, with an ambient temperature of ≤ 50 ℃.

Safety device testing: The response time of the photoelectric protection device is ≤ 20ms, and the effective sensing distance is adjusted to 50-100mm. After the emergency stop button is triggered, the equipment needs to completely stop within 0.5 seconds.

3、 Debugging and acceptance

No load test: Run continuously for 30 minutes, check that the bearing temperature rise is ≤ 35 ℃ (ambient temperature+35 ℃), and the noise is ≤ 75dB (A). The repeated positioning accuracy of each axis should be ≤± 0.1mm (tested with a dial gauge).

Load testing: Conduct trial production at 80% of the maximum design speed to check for grid position deviation (usually ≤ 0.5mm) and notch burrs (≤ 0.1mm). Sampling inspection of 10 finished products, the spacing error between partitions must meet the requirements of the drawing (such as ± 0.3mm).

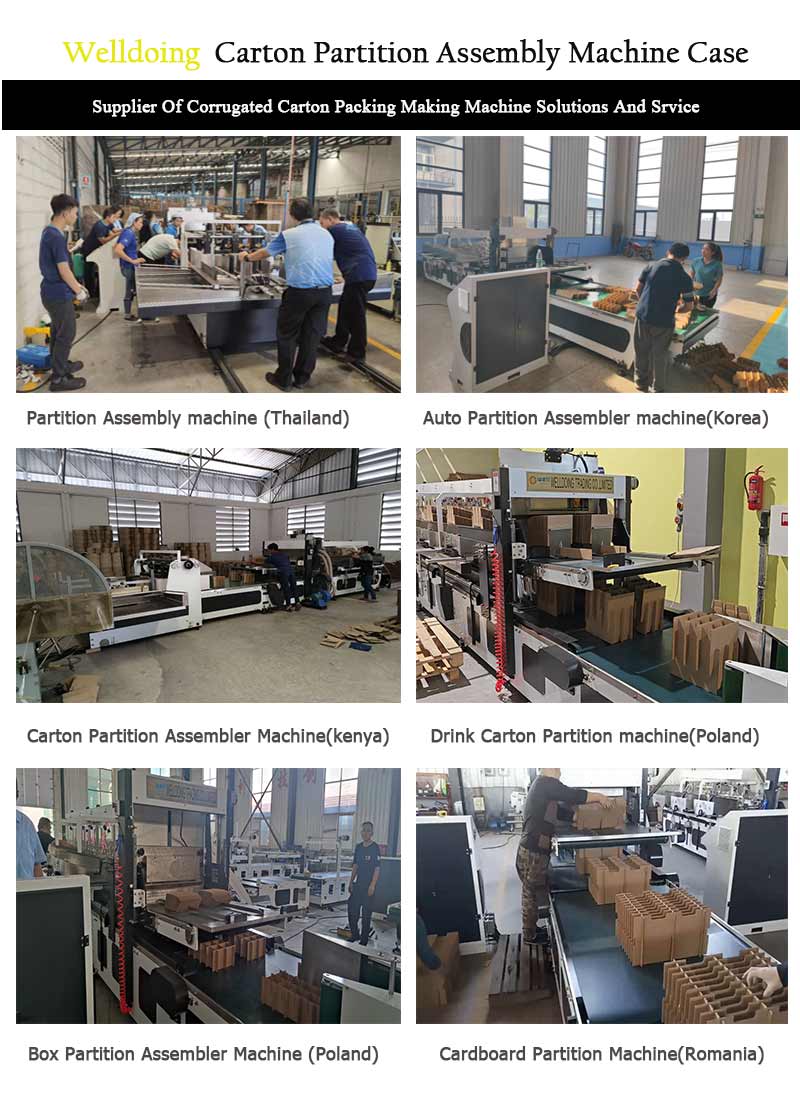

After installation, the automatic partition assembly insert machine supplier’s technical personnel need to perform final calibration, and the operators can only operate independently after passing the training. Keep the installation and debugging report as a warranty certificate.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: May-28-2025